ELECTRIC BRATT PAN WITH MIXER, 300 L., INDIRECT HEATING EXB/300I

The pan is provided with a mixer with adjustable speed and possibility to automatic reverse.It built with radial arms or scraping blades in stainless steel and insert in ceramic teflon.The mixer can be easly removed for cleaning or maintenance.

Manufacturer: DIAMOND

Available in:

3-4 weeks

Dimensions (mm):

1875x1650x1135

Power (kW):

37

Weight (kg):

950

Power supply:

400/3N 50Hz

Volume (m3):

4,9

Product description

ELECTRIC TILTING PAN WITH MIXER, 300 L., INDIRECT HEATING EXB/300I

- Tank diameter 960 mm, depth 500 mm.

- "Deep-drawn" tank, bottom made of polished AISI 316 stainless steel (25/10 mm thick) wall made of 304 stainless steel (20/10 mm thick). Indirect heating, double jacket made of 304 stainless steel (20/10 mm thick).

- Made of AISI 304 stainless steel, version on AISI 304 stainless steel columns (delivered with floor fixing kit).

- Covering: made of AISI 304 stainless steel (10/10 mm thick).

- Work surface: made of AISI 304 stainless steel (15/10 mm thick).

- "Deep-drawn" tank wall made of 304 stainless steel, bottom made of polished AISI 316 steel, resistant to salt corrosion and wear.

- Water tap for filling the tank.

- Mixer incorporated in the tank for a homogeneous cooking.

- Motorized tank tilting.

- Operation on the front side.

- "Deep-drawn" cover made of 304 stainless steel, self-compensating hinges allowing gradual closing and opening.

- Indirect heating, double jacket tank made of 304 stainless steel, filling by the safety group and control valves of minimum/maximum level of the double jacket.

- Pressure control of the double jacket by a 0.45 bar valve, with pressure gauge and vacuum valve

- Electric heating by INCOLOY resistors immersed in the double envelope, power regulation by means of an energy regulator.

- Safety thermostat, preventing water direction operation in the double jacket, as well as an operating pressure switch.

- Working temperature up to 100°C.

PLUS:

- Appliance of innovative design, combining the advanta-ges of cooking the product with continuous stirring and discharging the food into receiving trolleys with the discharge spout always at a constant height from the ground.

- The mixing blades can be customized to suit the types of product to be processed.

- The automation of the cooking parameters improves the final quality of the product and considerably reduces the kitchen personnel required.

MIXING SYSTEM

- The pan is provided with a mixer with adjustable speed and possibility to automatic reverse.

- It built with radial arms and scraping blades in stainless steel and insert in ceramic teflon.

- The mixer can be easly removed for cleaning or mainte-nance.

SUPPORT FRAME AND PANELS

- Stainless steel frameThermal insulation assured by high density ceramic fibre 64/128 Panels in stainless steel, fine satin finish.

INDIRECT ELECTRIC VERSIONS - WITH JACKET

- Heating by means of INCOLOY heating elements with adjustable power regulator.

- Safety thermostat to prevent overheating and keeps the equipment from operating without water.

- Jacket water level control taps max/min with the option of automatic filling.

- Jacket pressure control by working pressure switch and spring-loaded safety relief valve calibrated at 0,45 bar, vacuum valve and pressure gauge.

STIRRING SYSTEM

- Removable stirrer in AISI 316 stainless steel with adjustable speed between 7 and 28 r/m with force up to 386 N·m.

- Possibility to invert direction with electronic selector.

- Radial arms in stainless steel and ceramic Teflon scraper blades.

- Excellent also for viscous products.

MONITOR PLC

- Allows the management and customisation of up to 100 cooking programmes, which can also be modified during processing.

- Features a touch screen and manual controls to activate water filling, tilting and stirrer movement.

- Features acoustic buzzers and warning messages (in yellow) for correct operations or alarms (in red) in case of malfunction.

- All parameters can be customised, viewed and modified even during cooking (name, water delay/filling, times, temperatures, probes, stirring speed, time etc.)

TYPES OF USE

Treatable foods:

- Thick soups

- Thin soups

- Pasta

- Rice

- Sauces

- Boiled various

- Broths

- Dairy-based products

- Boiled vegetables

- Creams

- Marmalade

- Mashed potatoes

- Legumes

TYPE OF WORK:

- Boiling

- Mixing

ACCESSORIES

- Draining tap 2″ AISI 316 clamp attack

- Butterfly valve outlet 2,5” ISO DN50 AISI304

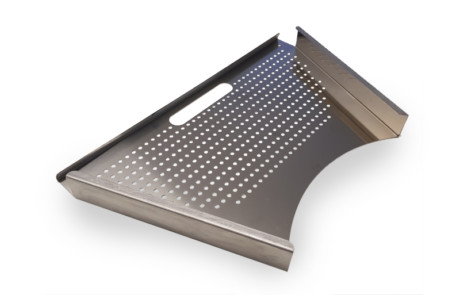

- Drain spout filter

- Hose shower

- Insulated cover

- Automatic water filling in jacket with probe

- Automatic air venting

- Tilting thermal trolley

Attachments