ELECTRIC TILTING PAN WITH MIXER, 200 L , INDIRECT HEATING EXB/200I

ELECTRIC TILTING PAN WITH MIXER, 200 L , INDIRECT HEATING EXB/200I

ELECTRIC TILTING PAN WITH MIXER, 200 L , INDIRECT HEATING EXB/200I

Diameter tank 760 mm, deep 500 mm."Deep-drawn" tank, bottom made of polished AISI 316 stainless steel (25/10 mm thick) wall made of 304 stainless steel (20/10 mm thick). Indirect heating, double jacket made of 304 stainless steel (20/10 mm thick).

Manufacturer: DIAMOND

Available in:

3-4 weeks

Dimensions (mm):

1675x1450x1135

Power (kW):

24,5

Power supply:

400/3N 50Hz

Weight (kg):

780

Volume (m3):

3,15

Product description

ELECTRIC TILTING PAN WITH MIXER, 200 L , INDIRECT HEATING EXB/200I

- Diameter tank 760 mm, deep 500 mm.

- "Deep-drawn" tank, bottom made of polished AISI 316 stainless steel (25/10 mm thick) wall made of 304 stainless steel (20/10 mm thick).

- Indirect heating, double jacket made of 304 stainless steel (20/10 mm thick).

- Made of AISI 304 stainless steel, version on AISI 304 stainless steel columns (delivered with floor fixing kit).

- Covering: made of AISI 304 stainless steel (10/10 mm thick).

- Work surface: made of AISI 304 stainless steel (15/10 mm thick).

- "Deep-drawn" tank wall made of 304 stainless steel, bottom made of polished AISI 316 steel, resistant to salt corrosion and wear.

- Water tap for filling the tank.

- Mixer incorporated in the tank for a homogeneous cooking.

- Motorized tank tilting.

- Operation on the front side.

- "Deep-drawn" cover made of 304 stainless steel, self-compensating hinges allowing gradual closing and opening.

- Indirect heating, double jacket tank made of 304 stainless steel, filling by the safety group and control valves of minimum/maximum level of the double jacket.

- Pressure control of the double jacket by a 0.45 bar valve, with pressure gauge and vacuum valve

- Electric heating by INCOLOY resistors immersed in the double envelope, power regulation by means of an energy regulator.

- Safety thermostat, preventing water direction operation in the double jacket, as well as an operating pressure switch.

- Working temperature up to 100°C.

PLUS:

- Appliance of innovative design, combining the advanta-ges of cooking the product with continuous stirring and discharging the food into receiving trolleys with the discharge spout always at a constant height from the ground.

- The mixing blades can be customized to suit the types of product to be processed.

- The automation of the cooking parameters improves the final quality of the product and considerably reduces the kitchen personnel required.

MIXING SYSTEM

- The pan is provided with a mixer with adjustable speed and possibility to automatic reverse.

- It built with radial arms and scraping blades in stainless steel and insert in ceramic teflon.

- The mixer can be easly removed for cleaning or mainte-nance.

SUPPORT FRAME AND PANELS

- Stainless steel frameThermal insulation assured by high density ceramic fibre 64/128 Panels in stainless steel, fine satin finish.

INDIRECT ELECTRIC VERSIONS - WITH JACKET

- Heating by means of INCOLOY heating elements with adjustable power regulator.

- Safety thermostat to prevent overheating and keeps the equipment from operating without water.

- Jacket water level control taps max/min with the option of automatic filling.

- Jacket pressure control by working pressure switch and spring-loaded safety relief valve calibrated at 0,45 bar, vacuum valve and pressure gauge.

STIRRING SYSTEM

- Removable stirrer in AISI 316 stainless steel with adjustable speed between 7 and 28 r/m with force up to 386 N·m.

- Possibility to invert direction with electronic selector.

- Radial arms in stainless steel and ceramic Teflon scraper blades.

- Excellent also for viscous products.

MONITOR PLC

- Allows the management and customisation of up to 100 cooking programmes, which can also be modified during processing.

- Features a touch screen and manual controls to activate water filling, tilting and stirrer movement.

- Features acoustic buzzers and warning messages (in yellow) for correct operations or alarms (in red) in case of malfunction.

- All parameters can be customised, viewed and modified even during cooking (name, water delay/filling, times, temperatures, probes, stirring speed, time etc.)

TYPES OF USE

Treatable foods:

- Thick soups

- Thin soups

- Pasta

- Rice

- Sauces

- Boiled various

- Broths

- Dairy-based products

- Boiled vegetables

- Creams

- Marmalade

- Mashed potatoes

- Legumes

TYPE OF WORK:

- Boiling

- Mixing

ACCESSORIES

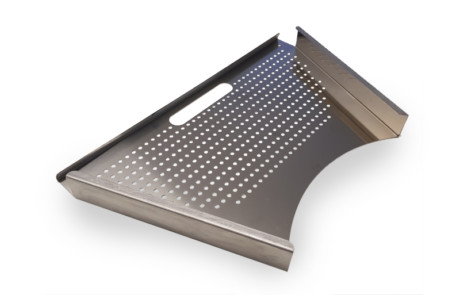

- Draining tap 2″ AISI 316 clamp attack

- Butterfly valve outlet 2,5” ISO DN50 AISI304

- Drain spout filter

- Hose shower

- Insulated cover

- Automatic water filling in jacket with probe

- Automatic air venting

- Tilting thermal trolley

Attachments