HOOD DISHWASHER DCS9/6-AC-RC

HOOD DISHWASHER DCS9/6-AC-RC

HOOD DISHWASHER DCS9/6-AC-RC

Integration of the "Green System H.R.S." Condenser vapor-recovery unit, big energy savings.Water softener continuously, incorporatedBasket 500x500 mm. Height of plates load Ø 450 mm

Manufacturer: DIAMOND

Available in:

2-3 days

Dimensions (mm):

710 x 800 x 1520/2229

Power (kW):

8,7

Weight (kg):

150

Power supply:

400-230/3N 50Hz

Volume (m3):

1,3

Base price 6 810 €

Salesprice with discount

Sales price 8 240 €

Price / kg:

Product description

HOOD DISHWASHER DCS9/6-AC-RC

- Water softener continuously, incorporated

- Integration of the "Green System H.R.S."

- Condenser vapor-recovery unit, big energy savings.

- Height of plates load Ø 450 mm.

- From 30 till 20 baskets/hour, PLD cycle 110", 150", continuous and " Sanitisation".

- 1080 plates/hour (60").

- Tank capacity 20 liters, warm holder 2,5 kW.

- Boiler capacity 12 liters, power 8 kW.

- 3 phases: wash, unload, rinse.

- Water consumption per cycle 3 liters.

- Vertical wash pump (double flux), auto-drain and auto-wash 0,95 Hp (230V/1).

- Standard discharge pump.

- Standard rinse pump (atmospheric boiler).

- Build: double skinned entirely in stainless steel AISI 304.

- Wash and rinse arms, upper and lower, rotating, lower in "molded" stainless steel, upper in "molded" polypropylene.

- Self cleaning sprinklers in stainless steel.

- Entirely stamped tank. "Integral" filter tank, in "molded" stainless steel.

- Pipes located outside the wash chamber.

- Stamped walls.

- Double filter of the pump in polypropylene.

- Stamped double skin hood, device opening and closing cover on connecting rods.

- Removable control panel for easy maintenance.

- Adjustable feet (160-220 mm).

- Function automatic water discharge tank, integrated in the control panel (no need to remove the plug manually).

- Automatic tank fill.

- Anti-return valve. Hot water rinse, stainless steel boiler.

- Tank and boiler temperature regulator.

- Micro switch for ending cycle at opening of hood.

- Security thermostat.

- Peristaltic dosage system for rinse and wash products.

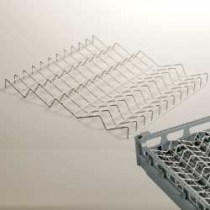

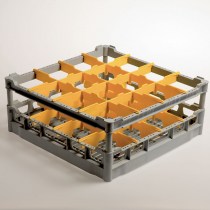

- Standard : 1 basket for plates, 1 general basket, 1 goblet, connection tube to main water supply and discharge tube.

- NB : all the machines from this range are guaranteed for use with water that has been treated with osmosis.

ADVANTAGE - H.R.S.:

- Warmth and steam recuperation system consisting of: a battery with double flow warmth-exchanger, heats up by crossing the cold water with the steam coming from the washing chamber.

- Low running costs: the water T° rises up to 25°C, the result is a 38-% saving of electric energy.

- Healthier work environment: by eliminating humidity emission in the environment, no more steam saturated of humidity up to 60°C.

- Easy installations: no need to install an additional hood to eliminate the steam, no extra sanitary or electrical connections needed!

- NB No compatible con Osmose.

ADVANTAGE - CONTINUOUS WATER SOFTENER :

- The softener continuously, constantly keeps softened water, regardless of the number of wash cycles, for perfect results and offers the advantage of not having to stop the dishwasher to allow the regeneration of resins during the micro-interruptions wash cycle used to regenerate the resins, while continuing to wash!

ADVANTAGE - BREAK TANK :

- The "break tank" is an AB type "anti-pollution" device (UK standards)

- It prevents the tank water (with detergents) to flow back into the distribution system .

- Its pump guarantees a constant pressure during the whole rinsing, the drying and hygiene are guaranteed by a T° of 85°C... until the last drop of water!

ADVANTAGE - SANITISATION :

This new sanitation program offers an additional guarantee thanks to a thermal disinfection phase during which the dishes are brought to a temperature of over 70 °C and remain there for a sufficient time to reach an A0 lethality index of over 30 (sanitary standard EN 15883). This standard guarantees the elimination of certain classes of germs and bacteria. This "A0" value can be set as required and the cycle time is automatically adjusted accordingly. The level of hygiene achieved with this cycle is therefore much higher than that which a traditional washing cycle can offer.

PLUS:

- CSD digital control panel (soft touch).

- PLD 4 cycles : 110", 150", continuous and " Sanitisation".

- EED energy saving.

- TCD thermostat control for a final rinse at 85 ° C.

- DRD accelerated preheating phase.

- DID automatic diagnostic in case of problems.

- ADD display of boiler and tank temperature (HACCP conform).

- DDD partial draining of the tank, evacuation by the bottom of the tank.

- RGD Constant rinsing T° of 85°C, stable pressure.

- BTD "Break Tank" anti-pollution device, AB type.

- CAD cycle auto-cleaning